Striped tarp durability is a critical factor when selecting this versatile material for applications like construction, agriculture, transportation, or camping. Known for its resilience and adaptability, striped tarpaulin (or striped canvas) is a popular choice. But what determines striped tarp durability? How can you identify a high-quality, long-lasting product? This article by Ktarp explores the essential factors affecting striped tarp durability and provides guidance on choosing the best option.

Key Factors Determining Striped Tarp Durability

Striped tarp durability depends on multiple factors related to material composition and manufacturing. Below are the primary elements:

1. Material Quality

-

Type of Plastic Resin: Striped tarps are typically made from polyethylene (PE) or polyvinyl chloride (PVC). PE tarps are lightweight and waterproof, with durability tied to fiber density (measured in GSM - grams per square meter). PVC tarps offer superior strength and weather resistance.

-

Virgin Plastic Ratio: Tarps made from 100% virgin plastic resin provide better tensile strength, flexibility, and weather resistance compared to those using recycled plastic, which may be brittle and prone to tearing.

-

UV-Resistant Additives: UV rays degrade tarps over time. High quality tarps include UV-resistant additives to enhance striped tarp durability by preventing brittleness, fading, and deterioration.

Learn more: Alibaba Ktarp Vina

2. Thickness and Weight

-

Thickness: Thicker tarps resist physical stress and punctures better. Choose thickness based on the intended use.

-

Weight (GSM): A higher GSM (e.g., 150-300 GSM) indicates a denser, more durable tarp. For example, a 150 GSM tarp is significantly more durable than a 90 GSM one.

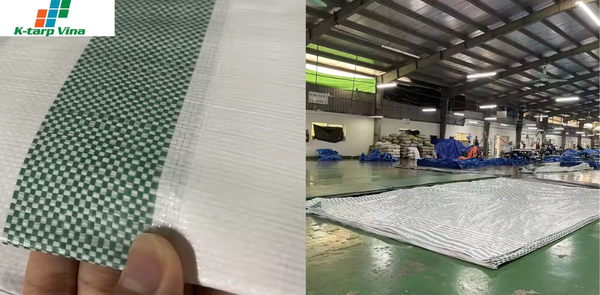

3. Weaving Technique and Fiber Structure

-

Fiber Density: Tightly woven fibers create a stronger, more waterproof surface, improving striped tarp durability.

-

Coating Structure: Quality tarps feature one or two layers of plastic lamination to ensure waterproofing and protect inner fibers. The coating quality directly impacts durability.

4. Edge Finishing and Grommets

-

Edges: Reinforced, heat-sealed, or sewn edges prevent fraying and tearing, especially in windy conditions, contributing to striped tarp durability.

-

Grommets: Sturdy, rust-resistant grommets (e.g., aluminum or galvanized steel) ensure secure fastening without tearing at stress points.

5. Usage and Storage Conditions

Even the most durable striped tarps can wear out if mishandled. Avoid dragging over sharp surfaces, overloading with heavy objects, or storing wet, as these reduce striped tarp durability. Proper care extends lifespan significantly.

How To Identify A Durable Striped Tarpaulin?

To select a tarp with high striped tarp durability, consider these indicators:

Check Technical Specifications

-

Material: Choose PE or PVC tarps with UV-resistant coatings.

-

Thickness (GSM or mil): Opt for a GSM of 150 or higher for long-term use.

-

Certifications: Look for fire resistance or waterproofing certifications.

Inspect the Surface

-

Smoothness and Uniformity: A smooth, even surface without flaws indicates quality manufacturing.

-

Color: Bright, consistent colors suggest effective UV treatment.

-

Edges and Grommets: Reinforced edges and sturdy, evenly spaced grommets enhance durability.

Test Waterproofing and UV Resistance

-

Water Test: If possible, test for water seepage. A quality tarp is fully waterproof.

-

UV Resistance: Check product labels or supplier details for UV-resistant additives.

Refer to User Reviews

Customer feedback or advice from construction and agriculture communities can reveal real world striped tarp durability. Online forums are valuable resources.

Conduct a Small Test

For bulk purchases, test a small tarp under real conditions (e.g., sun or rain exposure) to assess striped tarp durability before committing.

Tips For Maintaining Striped Tarpaulin To Enhance Durability

To maximize striped tarp durability, follow these maintenance practices:

-

Clean Regularly: Use water and mild soap, avoiding harsh chemicals.

-

Avoid Overstretching: Secure firmly but avoid excessive tension.

-

Store Dry: Dry completely before folding to prevent mold.

-

Use Appropriately: Match tarp thickness to the task (e.g., avoid thin tarps for heavy-duty construction).

Applications Of Striped Tarpaulin

Striped tarps are valued for their durability and versatility:

-

Construction: Protecting materials or shielding sites from weather.

-

Agriculture: Creating greenhouses or covering crops.

-

Transportation: Securing goods on trucks or ships.

-

Camping: Serving as tents or rain covers.

In short striped tarp durability hinges on material quality, thickness, weather resistance, and proper usage. To choose a durable tarp, verify specifications, inspect the surface, and consult reviews. With proper maintenance, a high-quality striped tarpaulin can deliver long-lasting performance for diverse applications.